Gas

Suppression Systems

Detect,

Alert,

Control,

Extinguish.

Gas

Suppression

Systems

Detect, Alert,

Control, Extinguish.

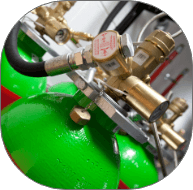

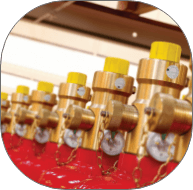

Automatic is a leading provider of inert and chemical gaseous fire suppression systems. Our track record for providing long term, sustainable gaseous fire suppression systems remains unbeatable and beyond reproach.

We have achieved this recognition by ensuring that the working life of all the different types of gaseous fire suppression systems that we provide has been safeguarded against replacement from potential future changes in health & safety and environmental legislation.

As a result, during the past four decades, we have protected virtually every type of business/process critical area – including data centres, transformer rooms, switches, control rooms, machine engines and many others.

Our continued success is reflected by the large number of global partnerships we maintain with some of the world’s top 100 companies within the industrial, commercial and power generation market sectors.

Our Gas Suppression Systems

Our Gas Suppression Systems

Inergen

INERGEN® is a mixture of 52% Nitrogen, 40% Argon and 8% CO2. However, in the event of a fire, when INERGEN® is discharged, it mixes with the air present in the room to create a mixture that comprises of 67.3% Nitrogen, 12.5% Oxygen, 17% Argon and 3.2% Carbon Dioxide.

This discharge mixture makes INERGEN® singularly unique. No other inert gas has the unique ability to rapidly extinguish a fire yet at the same time provide a safe environment for any person within the occupied area by actually decreasing cardiac distress and maintaining arterial blood oxygenation and mental performance in low oxygen environments.

Equally important, unlike some chemical gaseous fire suppression agents, INERGEN® does not, and could never create a reaction with a fire to create extremely harmful toxic or corrosive by-products.

INERGEN has been extensively used throughout the world as a preferred gaseous fire suppression agent for over 30 years and remains the longest surviving Halon replacement on the market to date.

Cost studies have shown that INERGEN is cost competitive when compared with the most popular chemical agents on typical systems. INERGEN does not take up premium floor space as the cylinders can be placed remotely from the protected risk.

Features:

• Fast acting

• No Ozone depleting Potential (ODP)

• No Global Warming Potential (GWP)

• Low life cycle cost

• Electrically non-conductive

• No breakdown / Decomposition products

• No risk of consequential damage

• Great Holding time characteristics

• Minimum downtime in the event of a gas discharge ( 24-48 hrs)

Applications:

• Data Centres

• Telecoms facilities

• Archive stores

• Laboratories /Clean Rooms

• Petrochem facilities

• Offshore

• Gas turbines

• Power generation

For further information on INERGEN Suppression Systems Design/Installation/Servicing or if you require a quotation or free site survey please contact any of the Gaseous Suppression Division.

IG55 is a clean fire suppression agent that is non-toxic, non-corrosive, odourless and leaves no residue.

Environmentally, IG55 brings nothing new and thus potentially damaging to the atmosphere. It comprises a pure 50:50 mixture of two gases which occur naturally, Argon and Nitrogen. What’s more, because the blended components have a density similar to air, the mixture is able to retain its concentration in the risk area for far longer than chemical alternatives.

IG55 meets important environmental criteria, with no global warming or ozone depleting potential. Because it is inert, it forms no breakdown decomposition products minimising the risk of consequential damage.

It is, in short, an acceptable alternative to HFC’s, being safe to use in occupied spaces and with the benefit of having been recognised by regulatory bodies around the world.

Features:

• Fast acting

• No environmental impact

• Low life cycle cost

• Electrically non-conductive

• Zero breakdown products

• No risk of consequential damage

Applications:

• Data Centres

• Telecoms Facilities

• Archive Stores

• Laboratories /Clean Rooms

• Petrochem Facilities

• Offshore

• Gas Turbines

• Power Generation

For further information on IG55 Suppression Systems Design, Installation, Servicing or if you require a quotation or free site survey please contact the Gaseous Suppression Division.

Nitrogen ( N₂ ) extinguishing system uses natural agents and offer fast and reliable extinguishing without harming the environment. In addition, the N₂ extinguishing system with natural agents can be precisely tailored to the applications, requirements and risks of fire thanks to their high flexibility regarding system planning and design.

Features:

• Fast acting

• No environmental impact

• Low life cycle cost

• Electrically non-conductive

• Zero breakdown products

• No risk of consequential damage

Applications:

•Data Centres

• Telecoms facilities

• Archive stores

• Laboratories /Clean Rooms

• Petrochem facilities

• Offshore

• Gas turbines

• Power generation

Argon (Ar) extinguishing system uses natural agents and offer fast and reliable extinguishing without harming the environment. In addition, the Argon extinguishing systems with natural agents can be precisely tailored to the applications, requirements and risks of fire thanks to their high flexibility regarding system planning and design.

Features:

• Fast acting

• No environmental impact

• Low life cycle cost

• Electrically non-conductive

• Zero breakdown products

• No risk of consequential damage

Applications:

• Data Centres

• Telecoms facilities

• Archive stores

• Laboratories /Clean Rooms

• Petrochem facilities

• Offshore

• Gas turbines

• Power generation

Carbon Dioxide is the original “clean” agent that suppresses fire without leaving behind a residue to damage sensitive equipment, and because there is no agent to clean up, you are back in business faster. Automatic Fire & Integrated Solutions offer both High and Low Pressure Systems.

Carbon Dioxide is a plentiful, non-corrosive gas that does not support combustion nor react with most substances. It is commonly compressed to the liquid state for storage in high pressure cylinders or low pressure bulk storage tanks. Upon release, it discharges under its own pressure giving the appearance of steam as its low temperature crystallises water in the air.

For fire suppression purposes, the discharge is designed to raise the carbon dioxide concentration in the hazard area. This removes the free oxygen which supports combustion and results in fire extinguishment.

The resultant lack of free oxygen dictates that total flooding hazards are evacuated immediately, prior to system discharge and carbon dioxide atmospheres produced by local application discharge must be avoided by personnel until the area has been vented and declared safe to return to work.

Features:

• Fast acting

• No environmental impact

• Low life cycle cost

• Electrically non-conductive

• Zero breakdown products

• No risk of consequential damage

Applications:

• Petrochem Facilities

• Offshore

• Gas Turbines

• Power Generation

• Printing Presses

For further information on Carbon Dioxide Suppression Systems Design, Installation, Servicing or if you require a quotation or free site survey please contact the Gaseous Suppression Division.

FM200® (HFC 227ea) is known chemically as Heptafluoropropane and is manufactured by Dupont. FM200® is a colourless gas which is liquified under pressure for storage. Like Halon 1301 it has a low toxicity level and is super pressurised with Nitrogen. It rapidly extinguishes most common types of fire through a combination of chemical and physical mechanisms.

FM200® contains no bromine or chlorine and therefore has zero Ozone Depleting Potential (ODP).

The atmospheric lifetime of FM200® is between 31 and 42 years.

FM200® has been found to be less toxic than Halon 1301, which makes it safe for use in the fully automatic mode in occupied areas.

Typically FM200® requires a design concentration of 7.9%, which is well below the 9% No Observable Adverse Effect Level (NOAEL) on cardiac sensitisation.

Features:

• Fast acting

• Electrically non-conductive

• Minimum cylinder storage space

Applications:

• Data Centres

• Telecoms Facilities

• Archive Stores

• Laboratories /Clean Rooms

• Petrochem Facilities

• Offshore

• Gas Turbines

• Power Generation

For further information on FM200 Suppression Systems Design, Installation, Servicing or if you require a quotation or free site survey please contact the Gaseous Suppression Division.

Novec Gaseous Fire Suppression Systems consist of Novec 1230 fluid which is a fluorinated ketone and is manufactured by 3M.

Novec 1230 fluid has low toxicity and has a boiling point of 49°C and therefore exists as a liquid at room temperature. Like halon 1301 and FM200 it is super-pressurised with nitrogen to 25 bar. Like most other chemical agents, it rapidly extinguishes through a combination of heat absorption (its main action) and some chemical interference at the flame front.

Novec 1230 fluid contains neither bromine nor chlorine and has zero ozone depleting potential.

The atmospheric lifetime of Novec 1230 fluid is estimated to be in the range of 3-5 days and with a global warming potential of 1, it is considered that the Novec 1230 fluid has no measurable impact on climate change. These attributes ensure that Novec 1230 fluid represents a truly sustainable technology.

Acute toxicity testing has shown that Novec 1230 fluid is safe at end use concentrations. The effective toxicity exposure limit is greater than 10% for both the acute inhalation exposure and cardiac sensitisation No Observed Adverse Effect Level (NOAEL) and set against low design concentrations, it offers margins of safety (up to 100%).

Despite having a low boiling point, Novec 1230 fluid is able to be effectively vapourised over a wide range of hazard temperatures. It is therefore available to protect most hazards traditionally protected with halon 1301 and will be particularly important in Marine applications and others where high margins of safety and long-term sustainability are considered to be important features.

Features:

• Fast acting

• No Ozone depleting Potential (ODP)

• No Global Warming Potential (GWP)

• Safe for use in occupied areas

• Requires minimal storage space

Applications:

• Data Centres

• Telecoms facilities

• Archive stores

• Laboratories /Clean Rooms

• Petrochem facilities

• Offshore

• Gas turbines

• Power generation

For further information on Novec 1230 Suppression Systems Design, Installation, Servicing or if you require a quotation or free site survey please contact the Gaseous Suppression Division.

Condensed aerosol fire suppression is a particle-based form of fire extinction.

It employs a fire-extinguishing agent consisting of: very fine solid particles as well as gaseous matter. The condensed aerosol microparticles and effluent gases are generated by the exothermic reaction; the particles remain in vapor state until the process of being discharged from the device. Then, it is “condensed” and cooled within the device and discharged as solid particles.

Compared to gaseous suppressants (which emit only gas) and dry chemical suppression agents (which are powder-like particles of a large size – 25–150 micrometres), the National Fire Protection Association defines condensed aerosols as those that release finely divided solids of less than 10 micrometres in diameter.

The solid particulates have a considerably smaller mass median aerodynamic diameter (MMAD) than those of dry chemical suppression agents. The particulates also remain airborne significantly longer and leave much less residue within the protected area.

Condensed aerosols are flooding agents. They are effective regardless of the location and height of the fire. This can be contrasted with dry chemical systems, which must be directly aimed at the flame.

The condensed aerosol agent can be delivered by means of mechanical operation, electric operation, or combined electro-mechanical operation.

Condensed aerosols’ primary extinguishing mechanism involves the fourth element of the fire tetrahedron by means of chemical reactions with the free radicals of the flame, therefore interfering with the combustion process of the fire. Typically, condensed aerosol particulates consist of potassium carbonate (K2CO3)) that are produced from the thermal decomposition of a solid aerosol-forming compound that includes potassium nitrate as an oxidizer. As the aerosol particles surround and come into contact with the flame, the particulates absorb the flame heat energy, breaking down and releasing large concentrations of potassium radicals (K+) (ions with an unpaired electron). The potassium radicals bond with the hydroxide (OH+), hydrogen (H+) and oxygen (O+) free radicals that sustain combustion, producing harmless by-product molecules like potassium hydroxide (KOH) and water (H2O).

K• + OH• = KOH

KOH + H• = K• + H2O

The potassium radicals are propagated since they are both consumed and produced by reaction with the fire radicals. Disrupting the reactions necessary to sustain the flame’s combustion, the cycle continues until the combustion’s chain reactions are terminated and the flame is extinguished.

Features:

• Fast acting

• No Ozone depleting Potential (ODP)

• No Global Warming Potential (GWP)

• Requires minimal storage space

• Cost Effective

Applications:

• Archive stores

• Lithium Ion Battery Containers

• Electrical Cabinets

• Generator /CHP Enclosures

• Petrochem facilities

• Offshore

• Gas turbines

• Power generation

• Industrial Machinery

Firetrace® is a self seeking suppression system which automatically detects and suppresses a fire at source. This is achieved by the Firetrace® detection tubing being routed through the risk area offering protection along its entire length. This detection tubing is designed to rupture at 110°C discharging the suppression agent at the point of Fire.

Firetrace® suppression systems may be used as a standalone device or can be fully monitored for interfacing with alarm system or a full shutdown of the equipment being protected.

Firetrace systems come with three separate offerings;

- Direct Firetrace System:

The Direct Firetrace System utilizes the Firetrace detection tubing as both the detection device and mode of delivery of the fire suppression agent. The portion of the tube nearest the hottest point of the fire ruptures forming a discharge nozzle. The pressure drop in the tube releases the entire contents of the cylinder through the burst directly onto the fire source.

Available with the following agents:

• Dry Powder

• Novec 1230

• Carbon Dioxide

- Indirect Firetrace System:

The Indirect Firetrace Systems use the trace tube for detection only. The Fire suppression agent is delivered via fixed piped diffusers. Once the detection tube bursts, the suppression agent is discharged through strategically placed diffusers within the protected enclosure.

Available with the following agents:

• Dry Powder

• Novec 1230

• Carbon Dioxide

• AFFF Foam

- Bi-Directional System:

The Bi-directional Firetrace System uses the trace tube for detection and delivery of a percentage of the suppression agent. The Fire Suppressant agent is delivered through the burst in the trace tube and via fixed piped diffusers strategically placed with the protected enclosure giving a discharge of both a direct and indirect system simultaneously.

Available with the following agents:

Available with the following agents:

• Dry Powder

• Novec 1230

• Carbon Dioxide

• AFFF Foam

Features:

• Cost effective

• Minimal extinguishant

• Totally pneumatic

• Easy to install

Applications:

• Electrical Cabinets

• Data/Server Racks

• Fume Cupboards

• Plant Machinery

• CNC / EDM Machinery